EQUIPMENT SELECTION

Although the selection of the correct equipment may depend on the installation and the conditions of the input water, an attempt will be made in this section to establish guidelines with which to make a good selection of equipment for the most standard filtration units.

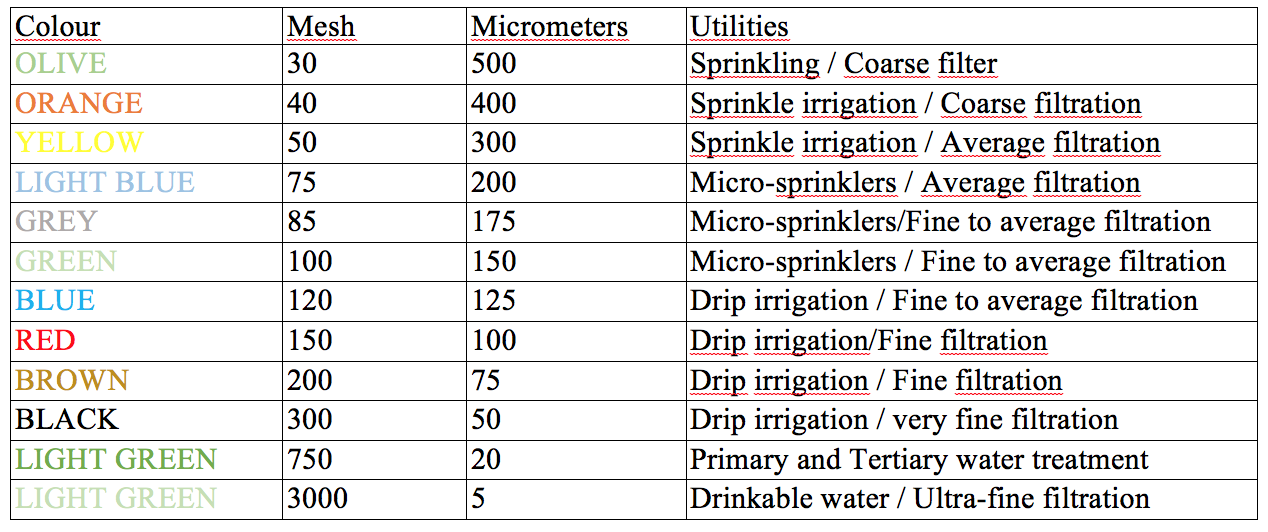

SELECTING THE MICRONAGE

To begin with the selection of the equipment, it is necessary to know what will be the micronage to be selected, here we will give a table with the most common uses of each one. NOVHIDRO filters distinguish micronage through disks color, this color is also defined in the table.

TYPE OF FILTER SELECCTION

Knowing the parameters of the installation where the equipment will be installed, the corresponding filter is selected.

With brackish water or brine with TDS> 10.000 ppm we will work with filter for saline waters, otherwise we will work with normal filters. With manual cleaning we will work with the manual filter, but if we are in installations with pressures greater than 3 bars it is advisable to work with the standard automatic filter, for installations with working pressures lower than 3 bar we will work with the filter at low pressure.

For micronage below 50 μm we will try to work with the input of 2″ because the necessary flow rate per filter is reduced and the inlet valve becomes cheaper.

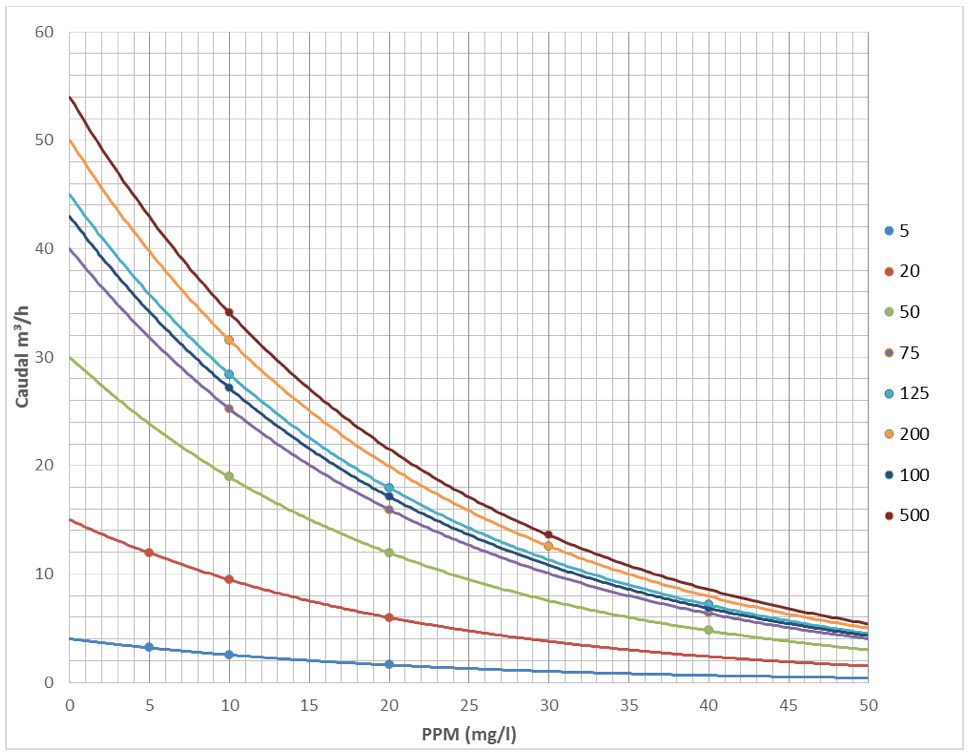

NUMBER OF FILTER SELECTION

The main parameter that is necessary to obtain the number of filters to install is the design flow, the micronage and the quality of inlet water. Below is a table that shows a moderate dimensioning respect to the flow rate to be introduced per filter depending on the degree of filtration to obtain.

Once we know the inlet flow per filter we can already select the necessary number of filters.

Up to 10 filters equipment: it is advisable to use equipment in line, up to 16 filters equipment it is advisable to use V equipment with three-way valves, up to 32 filters equipment it is advisable to use H-type equipment with three-way valves . If the installation is greater than 32 filters, equipment without valves should be considered. The collectors are dimensioned for speeds within 3-4 m/s.

EQUIPMENT HEADLOSS

The equipment headloss will always be changing, because they are always retaining dirt. So, what it can be established is a maximum with the differential pressure switch, from which the equipment will start backwash.

CONFIGURATION OF FILTERS

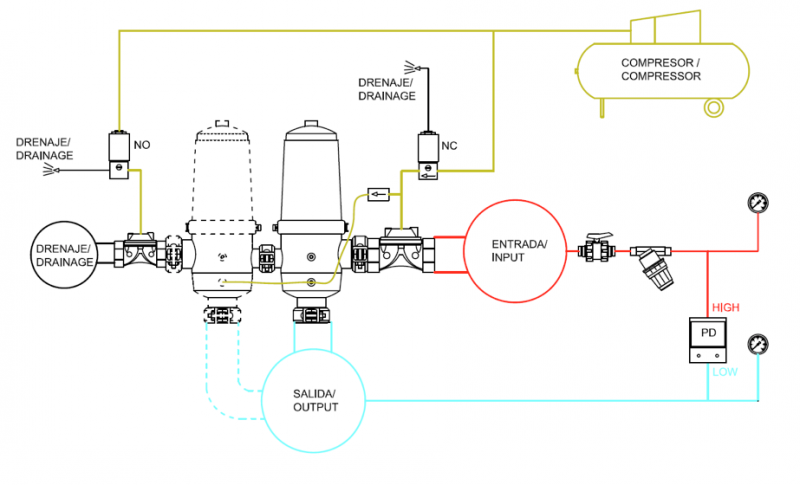

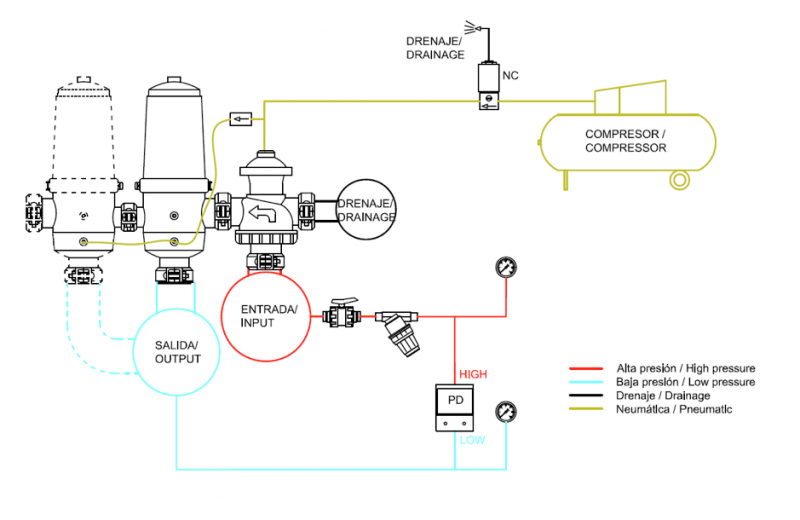

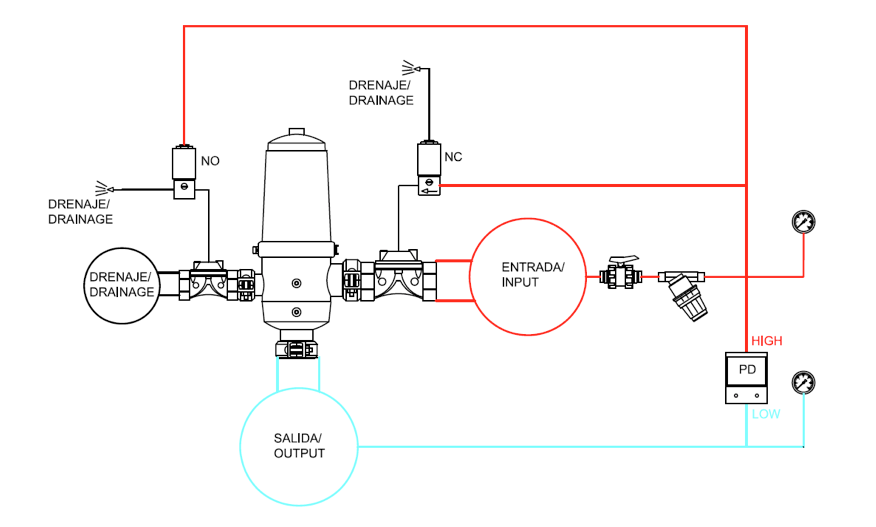

The main configuration of the equipment for working with two-way valves is shown in the following diagram, where the input to the equipment (high pressure) is used for the maneuverability of the hydraulic valves. From the inlet and outlet collectors, the pressure difference is obtained, through a differential pressure switch, which sends the signal to the programmer when it exceeds a set value in the same pressure switch. Programmer sends the signal to clean the equipment where the hydraulic valves come into operation by inverting the flow inside the filter. See below the assembly diagram with two-way valves.

The main equipment configuration for working with two-way valves is shown in the following diagram, where the input to the equipment (high pressure) is used for the maneuverability of the hydraulic valves. From the inlet and outlet collectors, the pressure difference is obtained, through a differential pressure switch, which sends the signal to the programmer when it exceeds a set value in the same pressure switch. Programmer sends the signal to clean the equipment where the hydraulic valves come into operation by inverting the flow inside the filter. See below the assembly diagram with two-way valves.

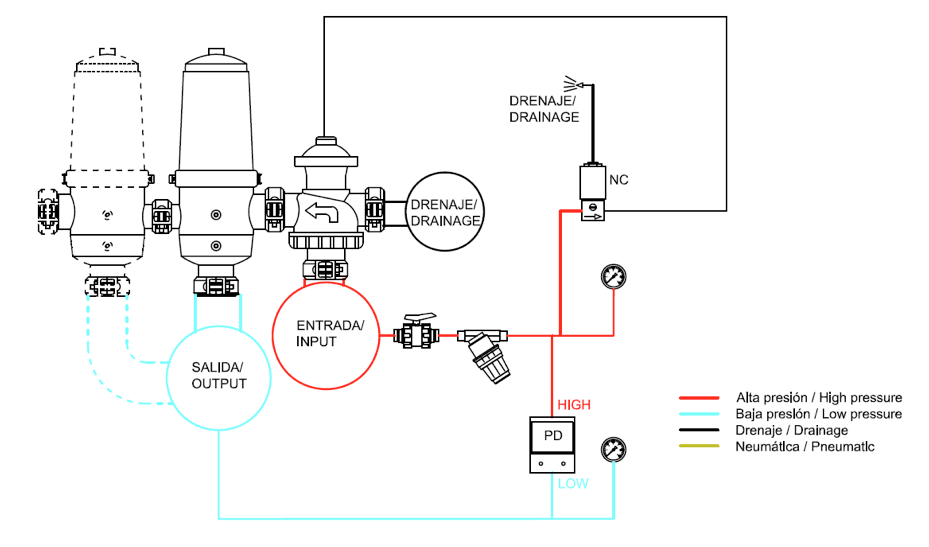

HYDRO PNEUMATIC CLEANING

Hydro-pneumatic cleaning in a NOVHIDRO filter consists of introducing compressed air through the ¼” socket of the filtered water filter when backwashing, thus reducing the cleaning time by increasing the flow through the pipes of cleaning and impacting the water mixed with air in the disk. With this we reduce the backwasing time, and the loss of water.

In equipment configuration an external compressor is used, and we take advantage of both to maneuver the valves and to introduce air to the filters. See diagram showing how this system works with both two-way and three-way valves.